Weifang Kaide Plastics Machinery Co., Ltd. was established in 2001,

focusing on plastic pipe extrusion technology for more than 20

years, especially for high speed pipe prodution line and

multi-layer composite pipe line.

Our main pipe extrusion lines are:

High Speed PERT/HDPE Pipe Extrusion Line

High Speed PPR-FG-PPR Pipe Extrusion Line

Inline Flat/Round type Drip Irrigation Pipe Extrusion Line

PEX-AL-PEX/PPPR-AL-PPR/PERT-AL-PERT Pipe Extrusion Line

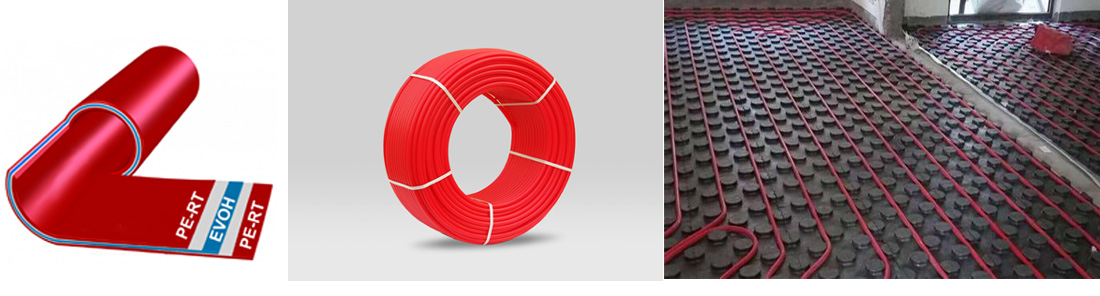

EVOH Oxygen Barrier Pipe Extrusion Line

Cross-linking PEX Pipe Extrusion Line

PVC reinforeced Hose Extrusion Line

Single Wall Corrugated Pipe Extrusion Line etc.

We have passed ISO9001 International quality system certification,

CE certification, American UL certification.

And was awarded as Advanced Enterprise, National outerstanding

Engerprises, Technology Contributions Prizes, High Technology

Enterprises, Creditable Enterprises,etc .

With advanced technology, excellent product quality and better

service, we have gained a larger market share for high-end plastic

pipe lines in the domestic market, and exported to Italy, Poland,

German, Finland, Russia, Ukraine, Iran, Algeria, South

Korea, Kyrgyzstan and other countries and area all over the world,

and successfully entered in to Europe and American market.

Any inquiry from you is highly appreciated. Sincerely hope those

words can lead us to a good cooperative relationship.